Redefining Quality and Innovation in Industrial Solutions

- Home

- About Us

- Products

- Painting Spray Guns

- Spray Painting Systems

- Powder Coating

- Robotic Painting Systems

- Double Diaphragm Pumps

- Paint Containers with stirrer and Pumps

- Dispensing Systems

- 2K Dispensing Systems

- Air Compressors

- Internal / External Pipe Coating Equipments

- Electrostatic Agricultural Sprayers

- Painting Accessories

- Painting Booth Systems

- Paint Kitchen Systems

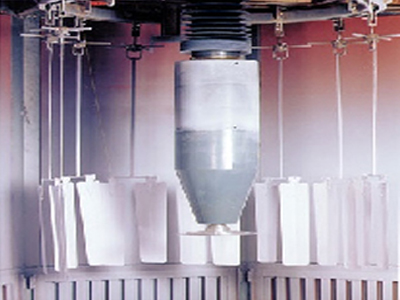

- Pneumatic Stirrers / Agitators

- Agarbatti Incense Stick / Dhoop Cone Spraying Machines

- Spraying / Painting SPM (Spacial Purpose Machines)

- Catalogues

- Gallery

- Clients

- Industries We Serve

- Home

- About Us

- Products

- Painting Spray Guns

- Spray Painting Systems

- Powder Coating

- Robotic Painting Systems

- Double Diaphragm Pumps

- Paint Containers with stirrer and Pumps

- Dispensing and Mixing Systems

- Air Compressors

- Internal / External Pipe Coating Equipments

- Electrostatic Agricultural Sprayers

- Painting Accessories

- Painting Booth Systems

- Paint Kitchen Systems

- Agarbatti Incense Stick / Dhoop Cone Spraying Machines

- Pneumatic Stirrers / Agitators

- Spraying / Painting SPM (Spacial Purpose Machines)

- Catalogues

- Gallery

- Clients

- Industries We Serve

- Enquiry